Imagine you’re an artist, your canvas is molten metal, and your brush, a casting furnace. Intriguing, right? Welcome to the world of jewelry metal casting, a process that’s as much a science as it is an art.

Jewelry metal casting is a method used to shape and mold precious metals into stunning jewelry pieces, capturing the raw power of earth’s treasures in artful designs. However, like any masterpiece, the process requires precision, skill, and most importantly, control over the elements, notably, temperature.

Key Takeaways

- The ‘Goldilocks Principle’ in jewelry metal casting highlights the importance of temperature control in creating flawless pieces.

- The casting furnace, through its precise temperature control, ensures a perfect balance of art and science in the crafting process.

- Temperature control in metal casting helps prevent common issues like porosity and incomplete casting, and assists in achieving complex designs.

- Heat treatment methods such as annealing, quenching, tempering, and aging require accurate temperature control to modify a metal’s properties effectively.

The Key Roles of Temperature Control in Jewelry Metal Casting

| Reasons for Temperature Control | Implication |

| Porosity | Incorrect flask or metal casting temperatures can cause porosity. A wall can form around the casting if the flask temperature isn’t hot enough, trapping gases inside the metal. If the casting temperature is too low, it may result in incomplete castings. |

| Heat Treatment | Post-casting heat treatment can alter a metal or alloy’s microstructure, and by extension, its mechanical and chemical properties. For instance, annealing can restore ductility to work-hardened metal. |

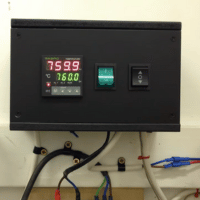

| Casting Quality | Integrated infrared temperature control can guarantee superior casting quality and repeatability. Improper temperature control can cause damage to the casting surface. |

| Metal Flow | Precise temperature control is critical for managing metal flow, especially when crafting complex designs or when vacuum casting is used to prevent air entrapment. |

The Art of Casting

Different metals melt at different temperatures. Gold, for instance, melts at around 1,064 degrees Celsius, while silver requires a slightly lower temperature of around 962 degrees Celsius. But why is this so important? Let’s dive into the science behind it.

Too Hot, Too Cold: The Goldilocks Principle

In jewelry metal casting, there’s a delicate balance we refer to as the ‘Goldilocks Principle’. If the temperature is too hot, you risk damaging the metal, leading to porosity or worse, burning the metal. On the other hand, if it’s too cold, the metal will not flow smoothly into the mold, leading to incomplete or flawed castings.

Every metal has an ideal casting temperature range, which is slightly above its melting point. By maintaining this ‘just right’ temperature, jewelers ensure that the metal flows evenly, fills up the mold properly, and forms a jewelry piece that’s both structurally sound and aesthetically pleasing.

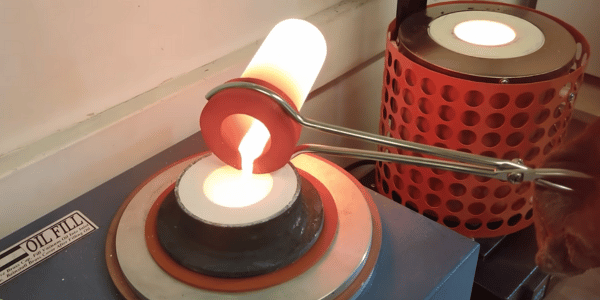

Enter, The Casting Furnace: A Symphony of Precision

The casting furnace, equipped with digital temperature control, is our silent hero in this narrative. It ensures precise temperature control throughout the casting process, achieving the perfect harmony between art and science.

Imagine you’re crafting a unique pendant for a client, designed to be a visual representation of their love story. The casting temperature needs to be just perfect to ensure every small detail – the intertwined initials, the heart motif, and even the tiniest of diamonds – sit perfectly in the pendant.

Now imagine the same scenario, but the furnace overshoots the temperature by a couple of hundred degrees. The overheated metal could bubble, creating holes in the pendant and destroying those delicate details. What should have been a symbol of love becomes, unfortunately, a symbol of a botched job.

Temperature Swings: Every Degree Matters

Furthermore, uncontrolled temperature fluctuations can wreak havoc in the jewelry metal casting process. Even minor temperature swings can alter the metal’s characteristics, leading to changes in hardness, color, and sometimes, causing irreversible damage.

Remember that beautiful rose gold engagement ring you once saw? Its stunning pink hue comes from the delicate balance of copper and gold. Overheat it during the casting process, and you’ll end up altering its signature color.

Frequently Asked Questions

Why is temperature control crucial in jewelry metal casting?

Temperature control in jewelry metal casting is essential to prevent porosity, improve casting quality, and enable precise metal flow, especially for intricate designs.

What happens if the metal casting temperature is too high or too low?

Overheating can cause damage to the metal, leading to defects like porosity, while insufficient heat can lead to incomplete or flawed castings.

What are some heat treatment methods used in jewelry making?

Common heat treatment methods include annealing, quenching, tempering, and aging. These processes alter the physical properties of the metal, such as hardness, ductility, and strength.

How does heat treatment impact the properties of a metal?

Heat treatment can change the microstructure of a metal or alloy, affecting its mechanical and chemical properties. For instance, annealing can restore ductility to work-hardened metal.

Conclusion

Mastering temperature control is paramount to the art and science of jewelry metal casting. It not only ensures the crafting of aesthetically pleasing pieces but also guarantees their structural soundness and durability. In the captivating world of jewelry making, the tale of transformation from raw metal to exquisite design is beautifully conducted by the invisible hand of temperature control.

Leave a Reply