Picture this: an artisan sculpting a unique design into a block of wax that will ultimately become a stunning piece of jewelry. It seems almost magical, doesn’t it? But it’s actually a process known as lost wax casting, an integral part of jewelry making that’s been honed and perfected over thousands of years.

This method allows the transformation of simple wax into silver, gold, or even platinum. Throughout this blog post, we will explore the origins, importance, and key stages of lost wax casting, making you privy to the secret alchemy behind each jewel in your collection. Get ready to embark on a journey from a lump of wax to a sparkling piece of art!

A Historical Perspective: The Emergence and Evolution of Lost Wax Casting

| Time Period | Region | Significance |

| 3500 B.C. | Near East | Appearance of lost wax casting |

| 2000 B.C. | Egypt | Use in crafting intricate jewelry |

| 16th Century | Europe | Flourishing during the Renaissance |

First Appearance: Origins in the Ancient Near East

Let’s set the time machine to approximately 3500 B.C. We land in the ancient Near East, and what we find there is truly remarkable. This is where archaeologists believe lost wax casting, also known as cire perdue, first appeared. Even then, craftsmen were using this innovative method to create detailed objects, including early forms of jewelry.

The Egyptian Era: Crafting Intricate Jewelry

Fast-forward a little to around 2000 B.C., and we’ll find ourselves in the civilization of ancient Egypt. The Egyptians loved their jewelry, and they used lost wax casting to make intricate pieces that still inspire awe today.

The Renaissance Flourishing: Artistry and Attention to Detail

Now let’s jump ahead to the 16th century in Europe. It was during the Renaissance that lost wax casting truly flourished as a jewelry-making technique. Goldsmith Benvenuto Cellini, known for his keen attention to detail, crafted elaborate pieces using this method, cementing its place in the annals of jewelry history.

Modern Development: Refinement and Innovation

While the basics of lost wax casting have remained the same over centuries, there have been important developments and refinements. Today, we use modern tools and technologies to improve the precision and efficiency of the process. However, the heart of the technique – creating a wax model, investing it in a mold, melting the wax to leave a hollow form, and then pouring molten metal into that form – is a testament to the ingenuity of our ancestors.

The Beauty of Timelessness

So the next time you admire a piece of jewelry, remember that you’re not just looking at a beautiful object. You’re witnessing the product of a process that dates back thousands of years, a process that has shaped human civilization in more ways than one. And that, dear friends, is the magic of lost wax casting!

The Art and Craft: Understanding the Process of Lost Wax Casting

| Step | Description |

| Crafting the Wax | The jeweler creates an original design out of wax. |

| Investing Model | A mold is created around the wax model using special material. |

| Melting & Casting | The mold is heated to melt the wax and molten metal is poured in. |

The Beginning: Crafting the Wax Model

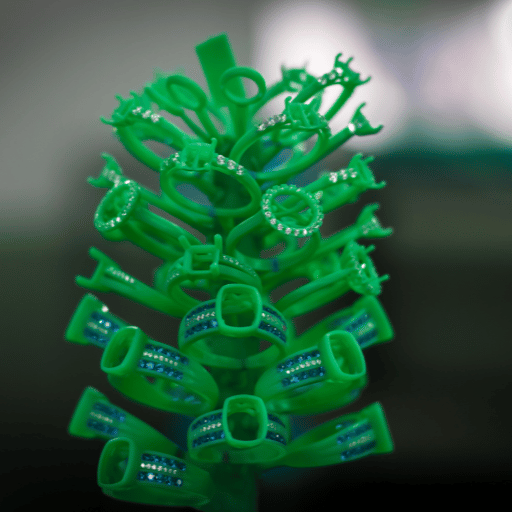

Let’s dive straight into the heart of the matter – how does lost wax casting actually work? It all begins with a model. The jeweler first creates an original design out of wax. This could be a ring, a pendant, or any other piece of jewelry. The level of detail that can be achieved in this stage is truly astounding, and that’s what makes this process so special.

Investing the Model: Creating the Mold

Once the wax model is ready, it’s time for the second step – investing the model. This involves creating a mold around the wax model using a special investment material, which is similar to plaster. The mold needs to be absolutely perfect to capture all the intricate details of the original wax model.

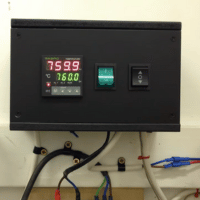

The “Lost Wax”: Melting and Casting

Now comes the part that gives this process its name. The mold is heated, and the wax inside it melts and flows out – hence, the ‘lost wax’. What’s left behind is a hollow mold. Molten metal is then poured into this mold to create the final piece of jewelry.

How Lost Wax Casting Transcends Boundaries of Design

In the universe of jewelry making, lost wax casting is a star that shines brightly. It’s an extraordinary process that, like a universal key, opens up a limitless world of design possibilities. Let’s explore why.

Harnessing the Power of Wax: Flexibility and Precision

One of the biggest advantages of lost wax casting is the flexibility and precision that wax provides. Wax can be shaped, carved, and manipulated in countless ways. This allows jewelers to create designs that range from the simplest shapes to the most intricate patterns and forms.

No matter how detailed or complex, these designs can be perfectly replicated in metal through lost wax casting. This is something that few other techniques can boast.

Casting Multi-Piece Designs: The Assembly Advantage

Another remarkable aspect of lost wax casting is its ability to create multi-piece designs. These designs are crafted as separate wax pieces, which are then cast and assembled to form the final jewelry piece. This method allows for a level of complexity and detail that can be breathtaking in its final form.

Emerging Trends: The Changing Landscape of Lost Wax Casting in Contemporary Jewelry Making

Just as it’s done for thousands of years, lost wax casting continues to evolve. The unchanging core of the process meets the changing tides of technology and design trends, creating exciting new possibilities in jewelry making. Let’s dive into the latest trends shaping the landscape of lost wax casting in the contemporary world.

Technological Innovations: From Handmade to Computer-Aided

In the traditional process of lost wax casting, the wax model is hand-carved, a labor-intensive process requiring significant skill. But with the advent of computer-aided design (CAD) and 3D printing technologies, this is changing. Today, jewelers can design a piece on a computer and then print it in wax, combining traditional craftsmanship with modern technology for more complex and precise designs.

Design Trends: Unique, Personal, and Ethereal

As for design trends, the call for unique, personalized pieces is shaping the future of lost wax casting. Consumers today value jewelry that tells a story, reflects their personality, or carries a symbolic meaning. This trend towards customization has allowed lost wax casting to come into its own, with its ability to create intricate, personalized designs.

Customization

Consumers are increasingly looking for unique and personalized jewelry pieces. Lost wax casting allows for customization, making it an ideal process for creating bespoke jewelry. Clients can completely customize their own design and try out the finished product virtually.

Looking Ahead: The Future of Lost Wax Casting in Jewelry Making

Lost wax casting has a long and storied past in jewelry making. But what about its future? What can we anticipate in the years ahead for this venerable technique?

Advancements in Technology: A New Era of Precision

With the rise of technologies such as 3D printing and computer-aided design, the future of lost wax casting is poised to reach new heights of precision and complexity. We can expect the process to become more streamlined and efficient, with jewelers being able to create even more intricate designs. These advancements also mean that personalized, bespoke pieces will become even more accessible to the everyday consumer.

The Drive for Sustainability: Eco-Friendly Practices

Another important trend we see influencing the future of lost wax casting is the increasing demand for sustainability in all aspects of life, including jewelry making. More and more jewelers are looking for ways to make their processes more environmentally friendly, from using recycled metals to eco-friendly investment materials.

Frequently Asked Questions

Why is lost wax casting popular in jewelry making?

Lost wax casting is popular due to its versatility. It allows for high precision and intricate detailing, making it suitable for creating complex designs. The technique also allows for the production of both unique pieces and exact replicas.

How has technology influenced lost wax casting?

With the advent of CAD and 3D printing, lost wax casting has seen significant advancements. Designs can now be digitally created and printed in wax, enhancing precision and enabling more complex designs.

How does lost wax casting contribute to sustainable jewelry making?

Many jewelers are incorporating sustainable practices in lost wax casting, like using recycled metals and eco-friendly investment materials. The process also creates less waste compared to some other methods, contributing to its sustainability.

Conclusion

Lost wax casting, an ancient method in jewelry making, continues to evolve, incorporating modern design trends and technology. Its remarkable versatility and precision secure its place as an essential tool in the jeweler’s workshop, shaping the past, present, and future of jewelry design.

Leave a Reply